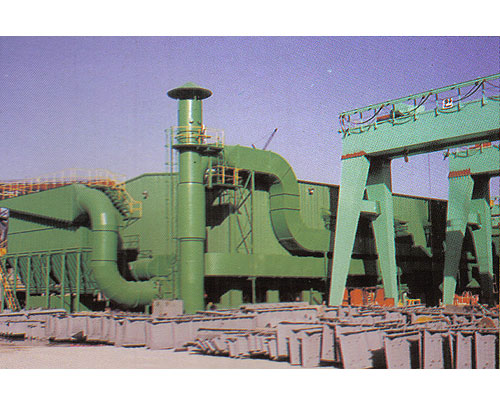

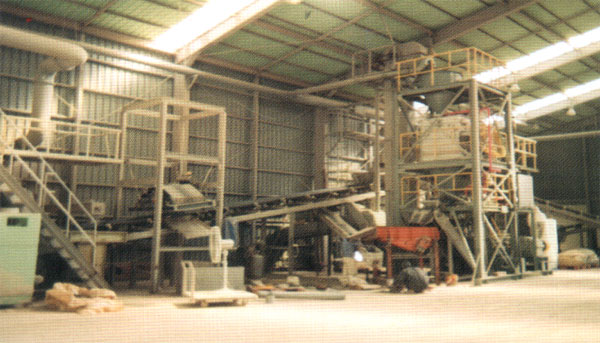

Through using most updated equipments and strict quality controls, DaeMyoung M tech Co.,Ltd manufactures Briquetting Line Environmental Equipments with high performance, efficiency, and reliability ratings.

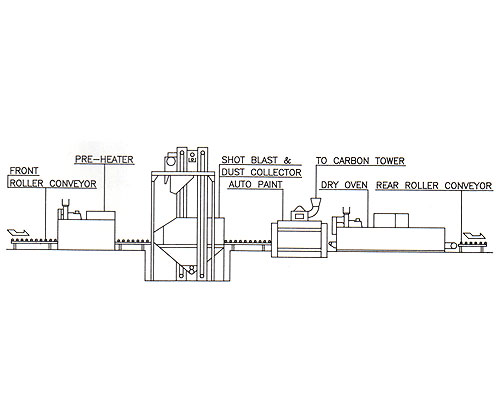

BLAST & PAINT LINE

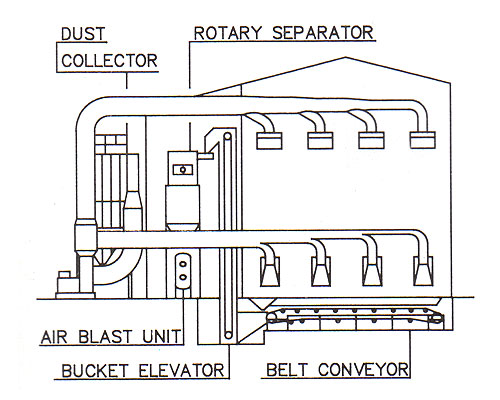

AIR BLAST EQUIPMENT

VACUUM RECOVERY

AIR BLAST UNIT

DUST COLLECTOR

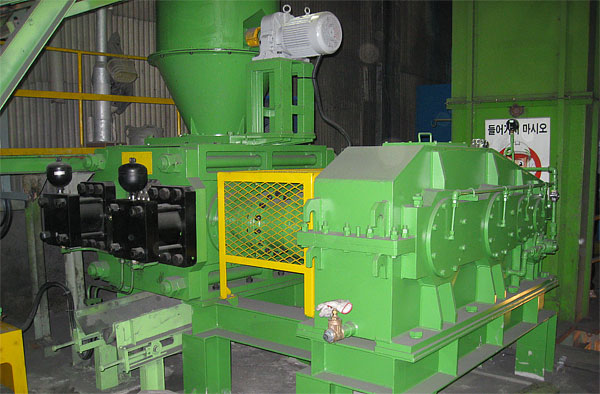

By-products of dust type (particulate, slag, scale, etc) can be effectively recycled to briquettes, which reduces an environmental destruction caused by wastes reclamation and reuses resources efficiently.

For smelting general metals such as iron, cooper, etc, oxide in these metals is deoxidized by making it react with reduction gas in high temperature, and ores had better be lumpy because reaction occurs on surfaces of ores as gas gets through spaces or gaps of lumpy ores piled. A lot of powder or granular powder is generated from ore mining and ore dressing, so it is mixed with binding agent in molding machine and pressed into shape of briquette.

| Motor | Motor used that inverter control is possible for normal speeds and adjustment of reducer |

|---|---|

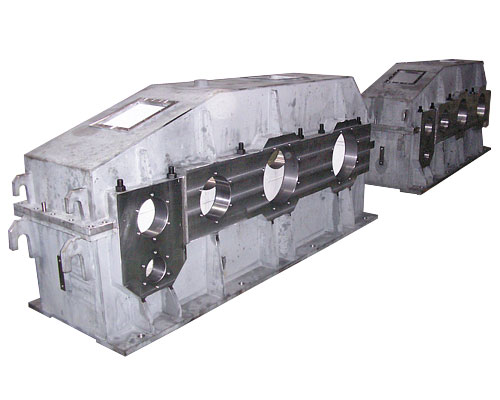

| Reducer | Equipment used to exchange low torque to high torque of low speed of motor at high speed rotation |

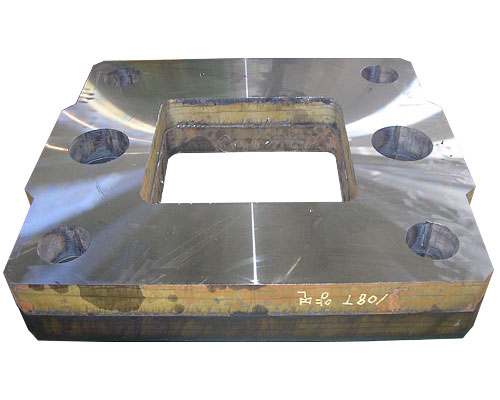

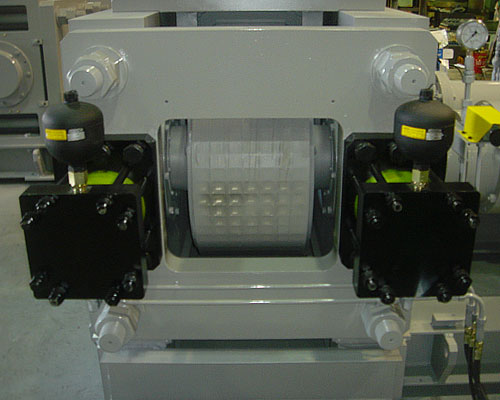

| Coupling | Chromium and nickel steel is used to increase abrasion endurance and to adjust intervals or lash segment roll |

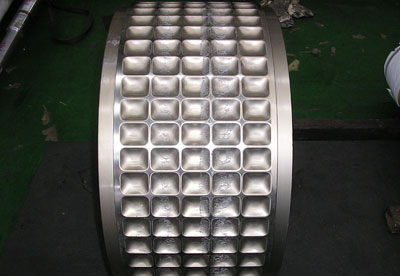

| Roll | Producing molds with Hi-Cr steel that complemented the abrasion endurance and shock, double rounding is Recommended to make flowing smooth |

| Cylinder | Briquetting is adjusted by oil pressure in order to keep an interval of Segment Roll regular |

| Screw Feeder | Spiral Screw is attached for regular raw materials supply |

Review the optimal conditions before designing and producing the test equipment with raw materials

PILOT M/C

MIXER

PRODUCT

POWER PACK

CONTROL PANEL

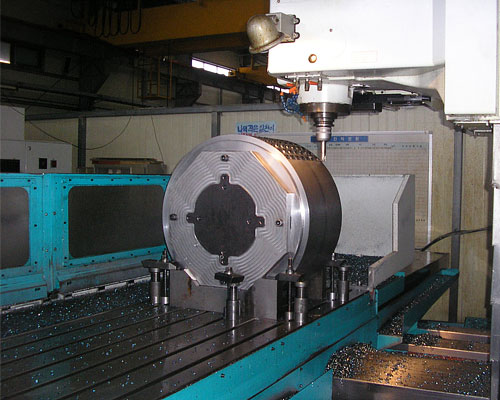

Rough Machining

Rough Machining

Hobbing

Rough Machining

Welding

Rough Machining

Rough Machining

Roll Assembly

Roll Assembly

Assembly

Hydraulic Unit

Assembly

Assembly

Running Test

Packing

20 Ton/Hr

24 Ton/Hr